Contract

CHPP down time is very expensive. Hand measurement is slow and prone to error.

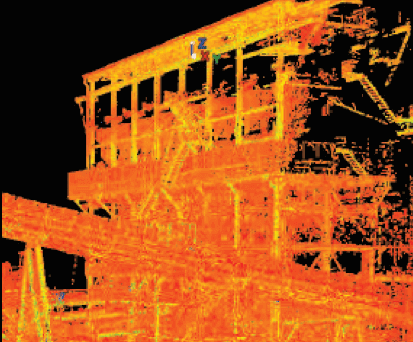

FIELD Engineers was approached by Peabody Energy to perform the terrestrial laser scanning of the CHPP and surrounding structures at the Coppabella Mine. This was done to facilitate many of the upgrades and part replacements planned for the plant.

Considerations

The site conditions meant that there were considerations that needed to be accounted for in the project planning including:

- Detailed measurements required for multiple projects.

- Data had to be collected in tight downtime window.

- Limited access.

- High level of accuracy required.

Challenges & Approaches:

Detailed measurement of multiple areas of the CHPP needed to be collected during a single plant shutdown. To ensure that all of the scanning was completed in the allowed down-time window, a detailed scanning plan was developed to maximise the data collected in each scan set-up.

SUCCESS:

The data collected from this scan allowed detailed design of: new desliming cyclones; spiral bank and magnetic separator upgrade feasibility study; ROM hopper support structure stabilisation; and replacement of a 180 tonne surge bin.

Outcomes

Entire CHPP scanned over 1 week period during shutdown and caused minimal disruption to ongoing maintenance activities.

Data collected used for design of plant upgrades, including detailed installation plans. Design of new components was possible with high accuracy reducing site fit-up.

Point cloud later used to build models for other areas under study without the need for additional site visits.

Recent case studies

Our diverse portfolio is a reflection of the expertise and skills FIELD Engineers possess and a testament to the commitment of our team.